| Product Types Used | Transfer Point Solutions , Chute Structure |

|---|---|

| Solution | MartinPLUS® Process Improvement |

| Industry | Coal-Fired Power |

| Customer | Entergy Operations Services, Inc. Independence Generating Plant, Newark, Arkansas |

Problem

In normal operations, Conveyor 4B, a 72-inch (1800 mm) feeder belt, loads coal onto the 72-inch (1800 mm) belt of Conveyor 5A. Plant engineers wanted to be able to bypass Conveyor 5A and load material directly from Conveyor 4B onto Conveyor 10A. The plant needed engineering assistance to accomplish this redesign and avoid bottlenecks and plugs in the new chute.

Solution

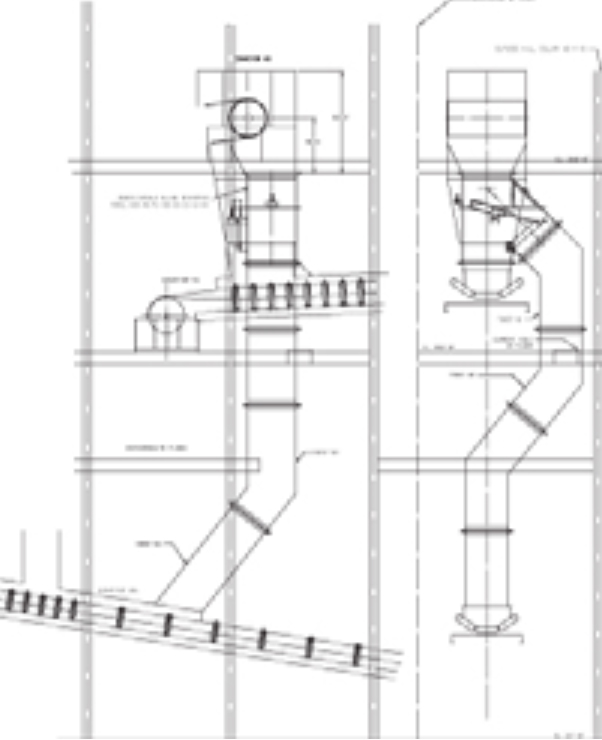

Following a site survey, MartinPLUS® Process Improvement specialists designed a flop gate for installation between Conveyors 4A and 5A. They also developed the chutework to connect the flop gate to Conveyor 10A. This chute required a material drop of about 45 feet (13.7 m) with a lateral offset of approximately 10 feet (3 m).

Martin Engineering prepared conceptual drawings. After plant approval, Martin developed detailed fabrication drawings of all chute work sections for local fabrication and installation.

Results

The reengineered chutework fit within 1/16 of an inch (1.5 mm) of desired location. Material flow rate achieves operating goals.

We've solved your problem somewhere before!

While your problem seems unique and frustrating, with 70+ years of solving similar problems around the world, and with the most experienced and educated people on our teams, we can assure you that we’ve “Been There, Done That.” At least close enough to know what needs to be done next and adjust for your situation.

Put Us To The Test For Free! Let Us Give You a Solution.