| Product Types Used | Air Cannon Solutions , Air Cannons |

|---|---|

| Solution | Installation |

| Industry | Cement |

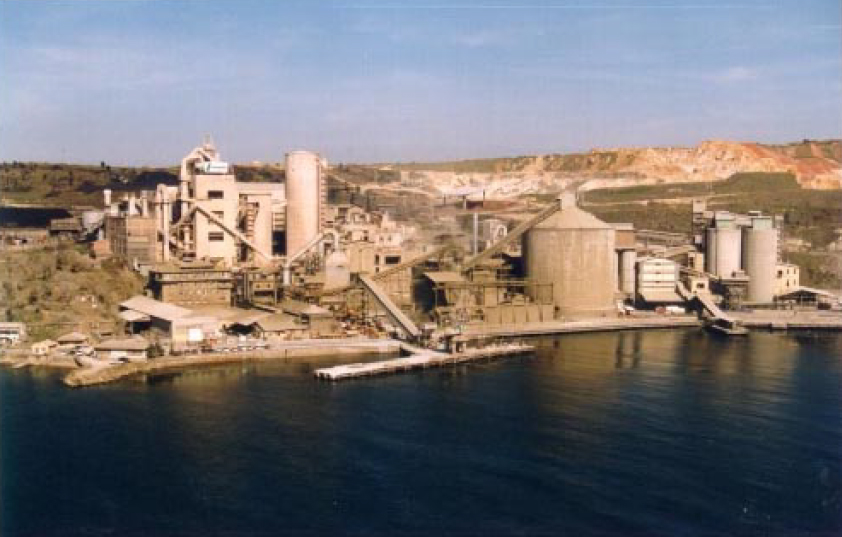

| Customer | Lafarge Cimento, Turkey |

Problem

Located southwest of the of Istanbul, Lafarge Cimento Darica Fabrikas produces 1,100,000 metric tons per year of clinker from one line. However, air cannon systems supplied by competitors were not working properly, leaving material buildups in the preheater tower. The buildups required manual cleaning at least two hours every shift, and a monthly slowdown for a major cleaning. Plant officials scheduled installation of 31 Martin® Air Cannons in 90 days. But then, one day later, plant officials called Martin Engineering Turkey, explaining the plant had to shut down due to refractory problems and they hoped to use the eight-day outage to install the new air cannons immediately.

Solution

Martin Engineering Turkey rose to the challenge, delivering 31 high temperature nozzles, 20 air cannons and the airline components and control systems to the plant within three days. With the delivery came two MartinPLUS® Service technicians who began the installation project. For four days, the installation crew never left the Lafarge plant. They supervised the installation and helped program the firing sequences. The 11 remaining air cannons were delivered within the week and installed. At the end of the second week, as the plant went back in full production, all 31 air cannons were operating.

Results

Martin Engineering Turkey completed delivery and installation on short notice, fitting the outage schedule and meeting the needs of the customer. Officials at Lafarge Cimento expressed gratitude to Martin Engineering Turkey, for completing the project so quickly. Now, no manual cleaning is needed in the lower part of the preheater. As a result, Lafarge Cimento is already planning to install Martin Engineering air cannons in the upper part of the preheater and the clinker cooler.

We've solved your problem somewhere before!

While your problem seems unique and frustrating, with 70+ years of solving similar problems around the world, and with the most experienced and educated people on our teams, we can assure you that we’ve “Been There, Done That.” At least close enough to know what needs to be done next and adjust for your situation.

Put Us To The Test For Free! Let Us Give You a Solution.