| Product Types Used | Air Cannon Solutions , Air Cannons |

|---|---|

| Solution | Installation |

| Industry | Steel |

| Customer | Arcelor Mittal; Lazaro Cardenas, Michoacan, Mexico (Air Cannons) |

Problem

During the rainy season, Arcelor Mittal had a lot of buildup problems at their Lazaro Cardenas plant. The material was accumulating on the walls of the hoppers causing a continual headache for operating personnel and a consistent production bottleneck. To knock down the buildup, the plant resorted to hitting the walls with tools. The frequency of the production stoppages were proving to be too costly - with high labor expenses, shortened refractory life and reduced hoppers efficiency.

Solution

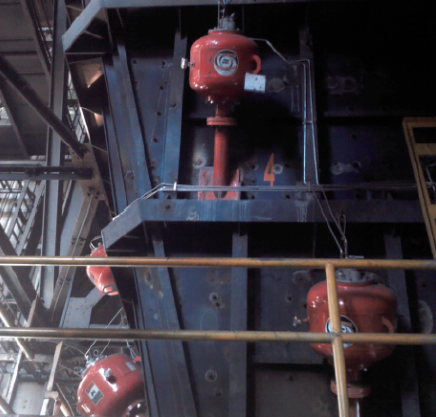

Martin Mexico recommended Martin® Hurricane Air Cannons to help solve the problem. A total of 68 Martin® Air Cannons were installed on 10 hoppers in total. With the powerful discharge from the reservoir of compressed air, the Martin® Air Cannons successfully removed the material from hoppers walls. Martin® Hurricane Air Cannons were designed for simple maintenance. The complete valve assembly can be removed in one easy step, working from one side of the tank. It can be replaced within minutes to keep running. There is no need to ever remove the tank from the vessel for service. The air cannons also fit in smaller places. The air cannon system, including blowpipes, air lines and control systems were installed by a MartinPLUS® Service team.

Results

To eliminate the blockages, the air cannons were strategically installed in a series and precisely sequenced for maximum effect, the network is timed to best suit the process conditions and material characteristics. The timed discharge of the air cannons can prevent accumulation that impacts process efficiency and raises maintenance expenses, while helping minimize the need for process interruptions and manual labor. Since the installation of the air cannons, the plant has virtually eliminated the need to manually clean the area. The customer can operate the air cannons from the control room and remain at operational efficiency.

We've solved your problem somewhere before!

While your problem seems unique and frustrating, with 70+ years of solving similar problems around the world, and with the most experienced and educated people on our teams, we can assure you that we’ve “Been There, Done That.” At least close enough to know what needs to be done next and adjust for your situation.

Put Us To The Test For Free! Let Us Give You a Solution.