Resources

| PDF - Printable Version of Case Study | Download |

Problem Solved!

We've been solving bulk material handling problems for companies around the word for over 70 years. Learn more about some of their experiences below.

| Products Used | Vibrating Dribble Chute |

|---|---|

| Product Types Used | Belt Cleaning Solutions , Belt Cleaner Accessories |

| Industry | Mining |

| Customer | Hindustan Zinc Limited - Chittorgarh, Rajasthan (India) |

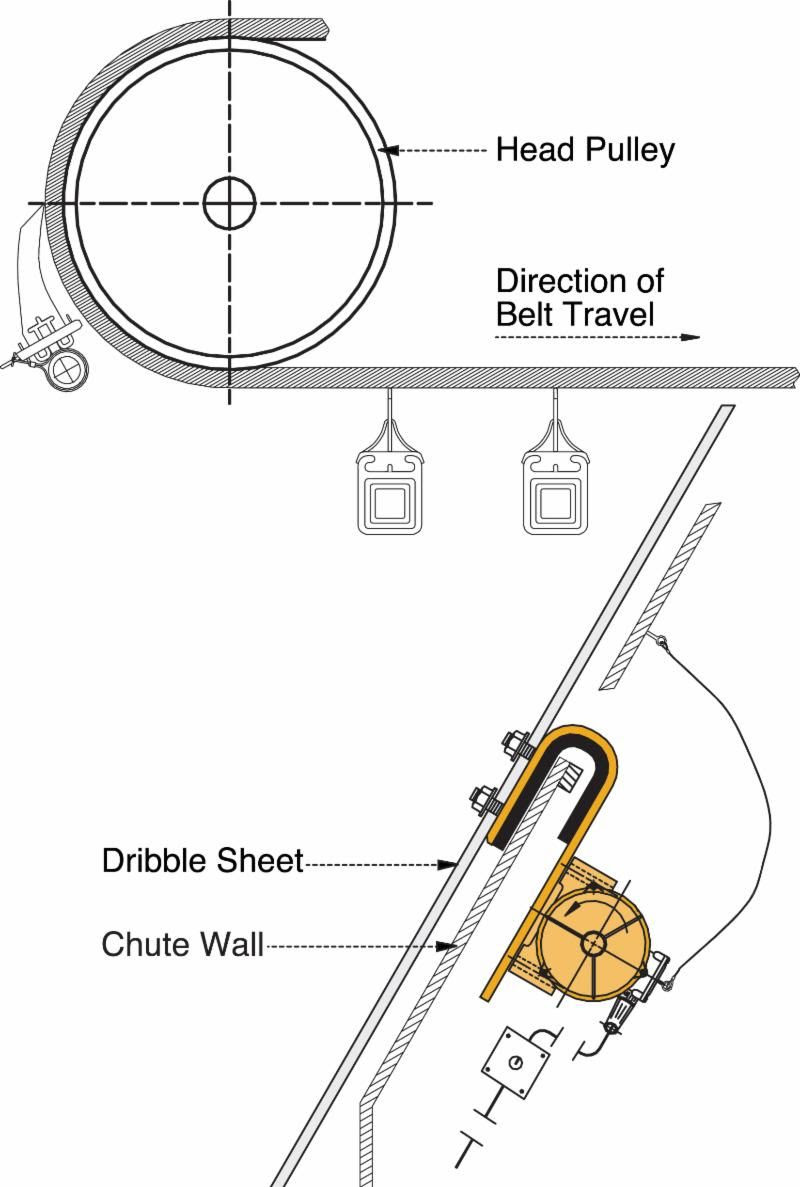

A subsidiary of Vedanta limited, Hindustan Zinc - India’s largest and world’s second largest zinc-lead miner situated in Northwest India, was experiencing severe amounts of buildup on conveyor 09 discharge chute walls transferring 100TPH zinc concentrate. To overcome this, plant managers had modified it with increasing the front gap and also tried using UHMW as well as improved SS liner plates having 2B finish. Still due to material moisture content (8-12%), material buildup issue had not been resolved, so the final solution in use was, deputing manpower for doing manual cleaning for every 8 hours. But such frequent manual cleaning was costlier and also risky considering worker's safety.

The Martin Engineering service engineer visited the site, audited the conveyor and recommended installing Martin® Vibrating Dribble Chute which uses an electric vibrator and a low-adhesion, low-friction UHMW chute liner to prevent buildup on discharge chute walls. Supplied Vibrating Dribble Chute used Cougar® Electric Vibrator Model B1-410-0A-2 with Adjustable Eccentric Weights. Includes ON/OFF switch with capacitors. It's mounting bracket incorporates rubber lining to isolate chute wall from bracket to reduce noise. UHMW Liner dribble sheet was field-modified to fit chute and provide necessary belt clearance.

Operators reported a significant reduction in buildup and no material clogging. Maintenance personnel no longer have to spend excessive manpower and time cleaning up, allowing them to focus their efforts on more productive activities. "We are very happy with the installation, product's performance and now we don't require unsafe manual clean-ups" said the plant's Associate Manager (Mechanical). Hindustan zinc ltd. continues a strong relationship with Martin Engineering and intends to replicate the same solution to other conveyors facing the same issue.

+91 20 66788270

Martin Engineering Company India Pvt. Ltd.

Plot 191, 192, 193, Vadu Khurd

Alandi-Markal Road, Phulgaon

Pune 412216, India

salesindia@martin-eng.com

+91 20 66788270