Martin Engineering Releases New Surfactant Dust System

Published: June 8th 2016

Complete Dust Suppression System for Bulk Material Handling

[Neponset, IL] – A global leader in bulk material handling technology has introduced a customizable dust control system that delivers application-specific components, controls and additives to significantly improve suppression vs. off-the-shelf products. The Martin® Surfactant Dust System is a turnkey solution comprised of modular elements that are configured to best suit the individual operating conditions and materials of each customer operation, with a broad array of options that includes customized spray, material sensors, programmable controls, surfactants and even remote monitoring. With a versatility not typically found in stock suppression methods, the new system is now offered alongside the firm’s large family of other dust management products, giving customers a wider range of dust control and containment choices for improved effectiveness and efficiency.

“Every application is a one-off, so it stands to reason that the solutions should also be unique,” observed Martin Engineering Dust Solutions Manager Mark Strebel. “Our goal is to actually prevent dust at the source if possible, using the optimum treatment method in each case. This approach allows us to offer a virtually unlimited combination of design options and accessories for maximum control.”

“Some applications can tolerate as much as 5% allowable moisture addition,” Strebel explained. “In those operations, spray bars can deliver plain water directly to the material for basic, economical dust control. In hazardous or explosive environments, a controlled fluid spray allows us to meter in additives and obtain the benefit of a residual effect,” he said. “In more sensitive applications, the limit may be .5% or less, and in those cases we can employ a specialized surfactant to minimize moisture addition and achieve effective dust management across a wide variety of materials and handling techniques.”

Strebel added that having this system as part of the company’s family of products puts Martin Engineering in a unique position to deliver the best solution for a given application, even if that means combining several technologies to work in concert with one another. “We are now able to address dust issues through prevention, containment, control or suppression,” he said. “Effective dust management is often not possible with just one approach, but the right combined solution will often deliver the end result at a reduced cost of ownership.”

Among the other available options, activation sensors can be used to manage the dust suppression system, dispensing the control agent only when material is present to reduce waste and cleanup. Automatic flow adjustment is also available to consistently deliver the appropriate amount of water and additives to reduce overspray and help control costs.

Air Filtration

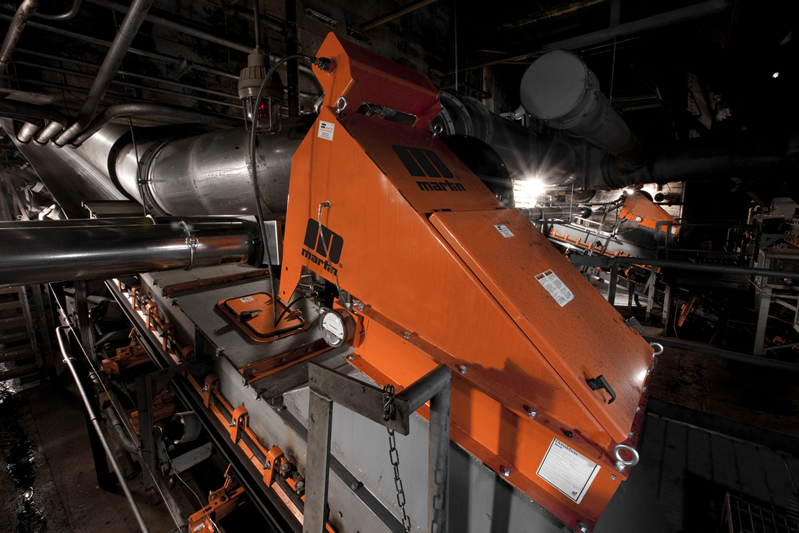

When the bulk material cannot tolerate any added moisture, filtration may be the critical piece in the dust-management system. Mechanical air filtration systems are installed to pull dust-laden air away from its source, separate the dust from the air, and exhaust the cleaned air.

Available in both passive and active designs, a passive system simply allows air to move through the filter medium, whereas active systems work like a vacuum cleaner to pull or push air through a filtration method to remove the particles.

The new Martin Engineering system can be configured to include passive elements such as Martin® Dust Bags to take advantage of positive air pressure for particle control without using any power. The bags self-clean by collapsing and depositing their contents back into the material stream whenever the air flow stops. Some containment is typically required, such as Martin® Dust Curtains or an enclosure.

The company also offers a family of Martin® Insertable Air Cleaners, which are installed directly at transfer points and other dust-generating points to collect airborne particles without using large fans and ductwork. Designed to remove dust from the air in applications such as conveyor loading and transfer points, silo vents and bucket elevators, the self-cleaning filters feature an automatic pulse cleaning system, which uses a short burst of air sent back through the filter media to dislodge accumulated material and return it to the bulk flow.